Job Aid: Class B Lap Splice Table* ... * 1 = uncoated Notes: 2 = epoxy coated w/ cover <3db or clear spc. <6db

Lap Splices – CRSI: Concrete Reinforcing Steel Institute

CRSI’s Reinforcement Anchorage and Splices includes tables of required lap splice lengths based on these variables. Contact splices–in which the bars touch and are wired together–are …

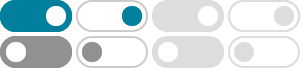

Lap Class A values are the required tension development lengths, ld; lap splice lengths are multiples of tension development lengths; Class A - 1.0ld and Class B = 1.3ld (ACI 318-14, …

Development lengths and lap splices in the tables provided in this chapter are intended to assist designer for design and detailing of reinforced concrete member.

Appendices > Appendix B - Development and Lap Lengths

(1) Min. lap for spliced bars, in., assumes fy = 60 ksi, per ACI 318-14, Equation (25.4.2.3a). (2) 40 bar diameters for fy = 40 ksi and 48 diameters for fy = 60 ksi

the area of reinforcement provided is at least twice that required by analysis over the entire length of the lap splice; and one-half or less of the total reinforcement is spliced within the required …

structure. There are two types of lap splices: contact lap and non-contact lap splices (see Figure a and 1b). The lapped sections of contact lap splices are wir together. Lapped sections of non …

Lap & Splice Lengths ACI 318-02 | PDF - Scribd

This document provides bar development and splice length requirements according to ACI 318-02. It includes tables with required lengths for bar development, lap splices, and hooks based …

WRI | Lap Splice Calculator - Wire Reinforcement Institute

Use K tr = 0 as a Design Simplification?

Splices for No. 11 bars and smaller are usually made simply by lapping the bars in a sufficient distance to transfer stress by bond from one bar to the other. The lapped bars are usually …